SKANDI KRAFT iTECH MIG 220 4R

iTECH MIG 220 4R 3-in-1 semi-automatic welding machine with the innovative MIG/MAG AUTO system. You select the material, thickness and wire diameter, and the optimal welding parameters are set. Thanks to the improved structure of the four-roll feeder, the wire feed is more stable and smoother for MIG torches up to 5 meters long. 3.5" LCD screen for intuitive and easy use in 4 languages.

The compact size and 14.6 [kg] weight make it mobile and convenient thanks to the transport handle. A comfortable and quiet operating mode (FAN STOP) that saves energy. For welding with three methods, both with gas bottle (MIG/MAG-AUTO) and without gas (FLUX), stick (MMA) and LIFT-TIG.

The iTECH MIG 220 4R is all about intuitive operation and advanced functions, with individually adjustable settings for PULSE, DUAL PULSE and INDUCTANCE technologies. The device has a 3-meter full-copper 3x2.5 [mm2] power cord and a 3-meter full-copper 25 [mm2] ground clip. The kit includes a 3-meter electrode holder and a 4-meter KD24 torch.

iTECH MIG 220 4R is ideal for welding materials from 0.5 [mm] to 12 [mm]

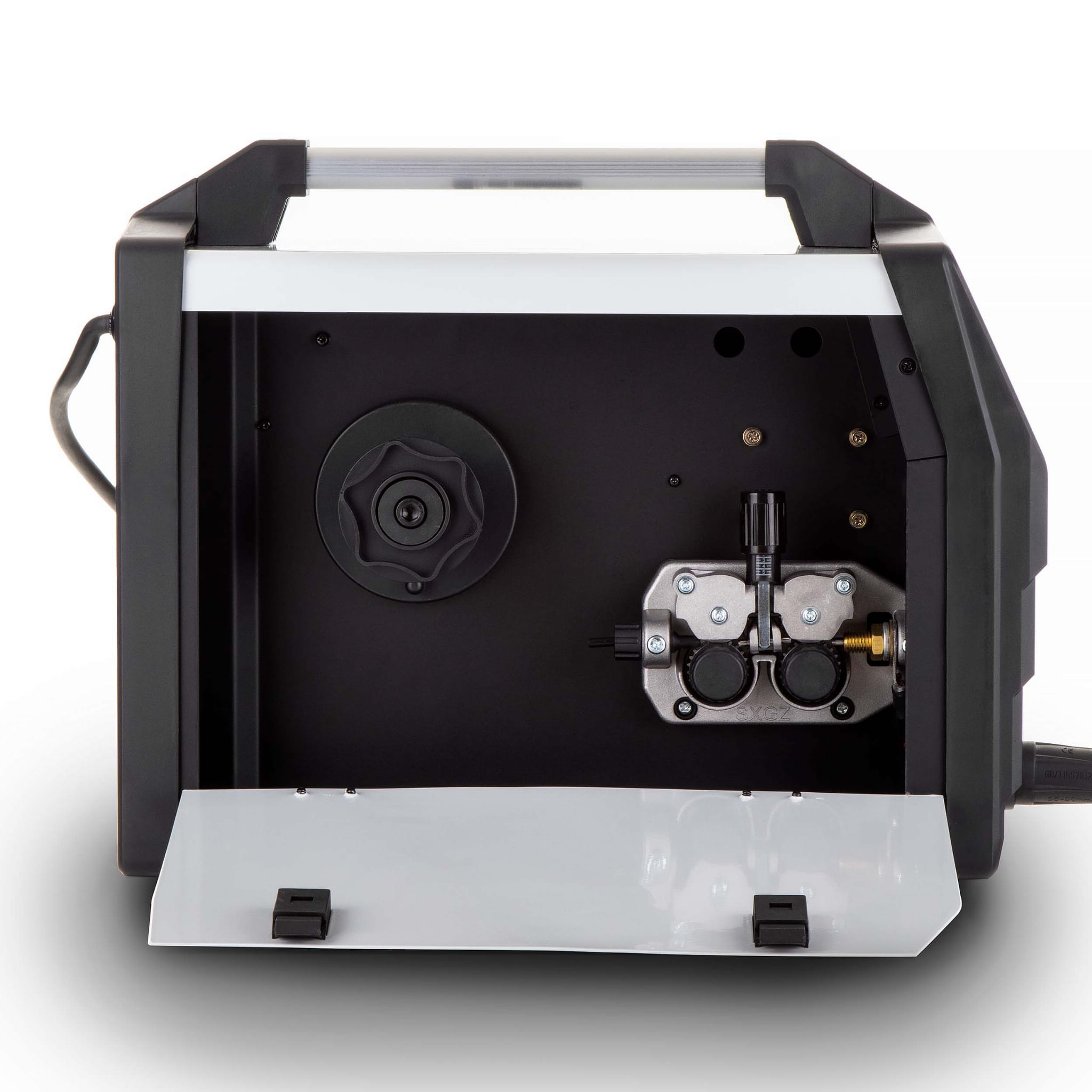

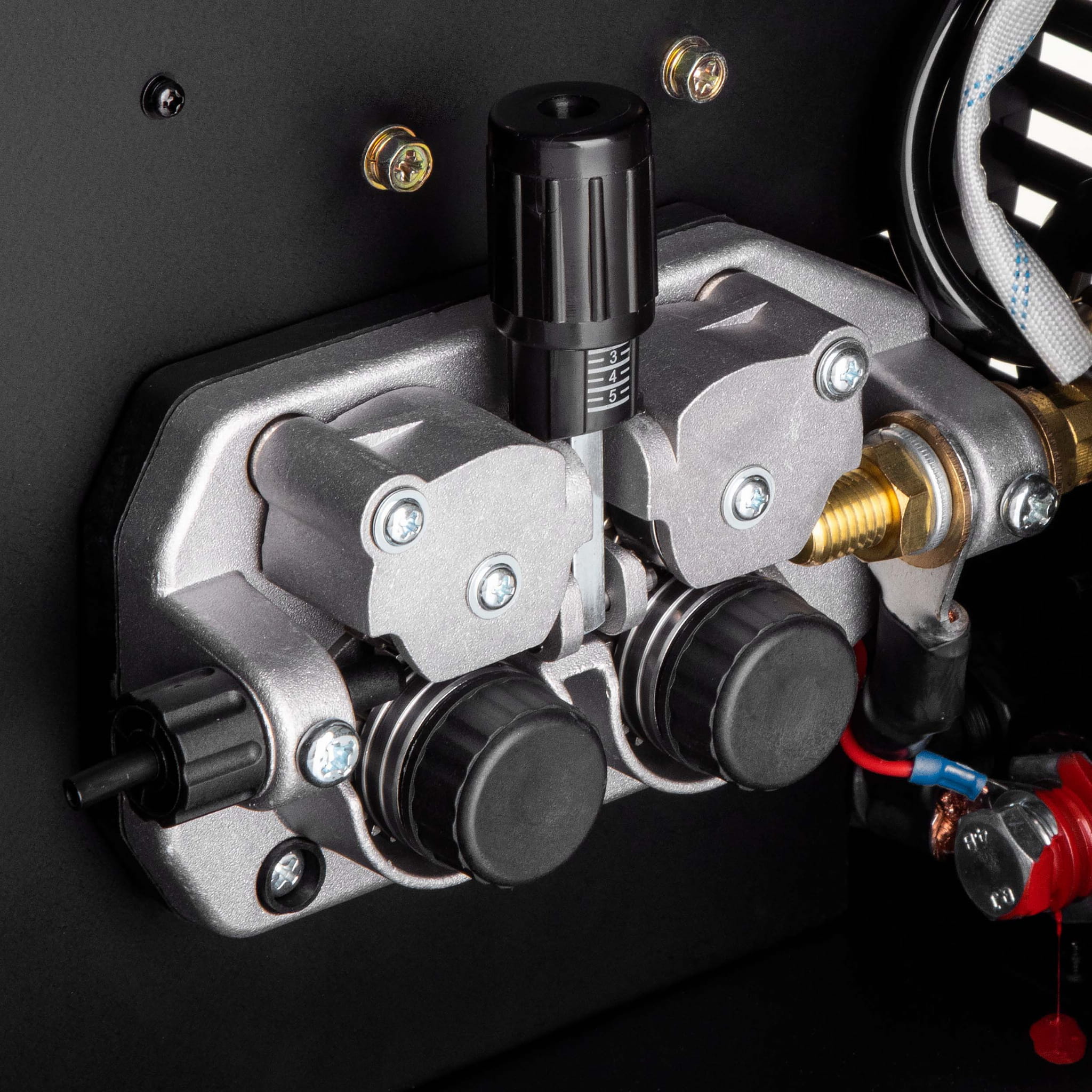

Welding machine with 4-roll wire feeder, so the wire is fed smoothly and evenly as needed. The main strength of the feeder redesign is compatibility with longer MIG torches.

MIG/MAG AUTO system - after entering the material, thickness and wire diameter, the optimal welding parameters are set.

PULSSI and DUAL PULSE welding improves penetration into the material to be welded, which improves the quality and strength of the weld.

Welding machine with an easy-to-read 3.5" LCD screen, four selectable languages and 18 memory channels for saving settings.

For welding with four methods: MIG/MAG AUTO, MIG/MAG, LIFT-TIG and MMA.

The FAN STOP system turns off the fan - so the welding machine is silent when it is on and fully functional, saves energy and attracts less dust. The fan switches on automatically when welding starts.

A SPOOL GUN holder (with integrated wire feeder) can be connected, which improves the transfer of material to the joint.

The device adjusts the welding current after the thickness of the material has been selected using the LIFT-TIG method. In the MMA method, after setting the material thickness, parameters and electrode diameter are proposed.

Handy selectors and a transparent panel make it easier to quickly start up the welding machine, even when wearing welding gloves.

2T welding. To start the arc, press and hold the torch button to weld, releasing the button will turn off the welding arc.

4T welding. The arc triggers a continuous arc by pressing and releasing the welding torch button. The arc is turned off by pressing and releasing the button again.

SPOT functions - designed for spot welding. The machine has a preset warm-up time and the user just sets the welding current. This function is mostly used in car repair shops

S_2T / S_4T functions - combines two welding techniques. Spot welding, where shielding gas is removed both before and after the welding process. In addition, 2T and 4T functions are used together in the S_2T/S_4 method so that welding starts and ends correctly.

Built with efficient IGBT components.

Functions of the welding machine

MIG/MAG AUTO welding

Automatic setting of the welding machine: after selecting the material, thickness and diameter of the wire, the machine sets itself to the optimal parameters. The welding current and other settings can be fine-tuned manually.

PULSE welding improves the transfer of filler material to the welding pool, which improves the quality and strength of the joint.

Optional 2T/4T for making longer welds more comfortably.

Selection of welding material (carbon steel, stainless steel, Al-Si - soft aluminum, Al-Mg - hard aluminum, Cu-Si - solder).

MIG/MAG welding

PULSE welding, which improves the transfer of the filler material to the weld pool, which improves the quality and strength of the weld.

2T/4T selection, for making longer welds more comfortably.

The SPOT welding function and support for S_2T and S_4T welding, i.e. shielding gas flows before and after the welding process, which rises from a lower current to the basic current and finally decreases again to the crater suppression setting.

Selection of welding materials (carbon steel, stainless steel, Al-Si - soft aluminum, Al-Mg - hard aluminum, Cu-Si - solder).

Selection of the thickness of the welding material.

Determination of wire diameter. Al-Si and Al-Mg (range 1.0-1.2), other materials (0.8-1.2).

Wire feed speed setting [m/min].

Welding current voltage setting [V].

Inductance adjustment ± [%].

Pulse frequency setting in pulse mode [Hz].

Pulse cycle adjustment [%].

MIG/MAG DUAL PULSE hot sauce

Peak feed rate [m/min].

Basic yarn feed speed [m/min].

Adjustable double pulse frequency [Hz].

Adjustable double pulse power [%].

MMA welding

Hot Start - enhances the start of welding by temporarily increasing the welding current at the beginning.

Arc Force - adjusts the length of the welding arc, reduces or increases the depth of fusion and reduces spatter.

VRD - extinguishes the arc when the electrode separates from the material for a safer welding environment.

Anti Stick - easier to remove electrodes when sticking.

LIFT-TIG hits out

Adjustable welding current [A], when the welding machine is set, it will indicate the thickness of the plate.

The LIFT-TIG function is equipped with a SOFT START module so that there is no risk of damaging the stick when starting the welding process.

Press and hold the "Return" button to restore factory settings.

Technical information

POWER SOURCE PARAMETERS

Power supply: 230 V

Frequency: 50/60 Hz

No-load voltage: 68 V

TECHNICAL PARAMETERS

MIG welding current: 40-200 A

MIG welding voltage: 16-24 V

Efficiency (at 40°C):

60% / 200 A / 24 V

100%/ 155 A/21.8 V

TIG welding current: 10-200 A

TIG welding voltage: 10.4-18 V

TIG efficiency (at 40 °C):

60%/200A/18V

100%/155A/16.2V

Stick welding current: 30-200 A

Stick welding voltage: 21.2-28 V

MMA efficiency (at 40 °C):

60 %/200A/28V

100%/155A/26.2V

Input device: 4 R

Thread spool diameters: D200

Maximum reel size: 5 kg

Diameter of the wire used in the welding machine: 0.8/1.0/1.2 [mm].

PHYSICAL DATA

Length x width x height: 48 × 21 × 38 [cm].

Weight: welding machine [net] 14.8 [kg], in box [gross] 21 [kg]

4-roll wire feeder for smooth wire transfer: yes

PULSSI and DUAL PULSE for better quality welding: yes

FAN STOP - turning off the fan when not in use: yes

Quick-connect gas hose (TYPE 21) connection: yes

SPOOL GUN external thread feeder connection: yes

VRD voltage reduction and safety improvement: yes

Arc Force welding arc length adjustment: yes

Hot Start fast arc ignition: yes

Anti Stick prevents electrodes from sticking: yes

Memory channels: 18

SKANDI KRAFT iTECH MIG 220 4R welding machine with integrated 3 m 3x2.5 [mm2] power cord

MIG torch KD24 type MB24 4 meters with Teflon graphite insert

Blue extra steel insert 4 meters for KD24 torch, for welding with wire diameter 0.6 -1.0 [mm]

All-copper electrode holder 3 meters, cross-section 25 [mm2]

Wire rolls: for steel 2x 0.8-1.0 V, for aluminum 2x 1.0-1.2 U.

Wire feed rollers size 22/10/30 [mm].

Gas cylinder mounting parts: 2 x gas regulator mounting clamps, 2 m gas hose, spanner, Allen key

Virtasuutin KD24, MB24 poltimelle (1x 0,8; 1x1,0; 1x1,0 ALU; 1x1,2 ALU)

User manual.

The compact size and 14.6 [kg] weight make it mobile and convenient thanks to the transport handle. A comfortable and quiet operating mode (FAN STOP) that saves energy. For welding with three methods, both with gas bottle (MIG/MAG-AUTO) and without gas (FLUX), stick (MMA) and LIFT-TIG.

The iTECH MIG 220 4R is all about intuitive operation and advanced functions, with individually adjustable settings for PULSE, DUAL PULSE and INDUCTANCE technologies. The device has a 3-meter full-copper 3x2.5 [mm2] power cord and a 3-meter full-copper 25 [mm2] ground clip. The kit includes a 3-meter electrode holder and a 4-meter KD24 torch.

iTECH MIG 220 4R is ideal for welding materials from 0.5 [mm] to 12 [mm]

Welding machine with 4-roll wire feeder, so the wire is fed smoothly and evenly as needed. The main strength of the feeder redesign is compatibility with longer MIG torches.

MIG/MAG AUTO system - after entering the material, thickness and wire diameter, the optimal welding parameters are set.

PULSSI and DUAL PULSE welding improves penetration into the material to be welded, which improves the quality and strength of the weld.

Welding machine with an easy-to-read 3.5" LCD screen, four selectable languages and 18 memory channels for saving settings.

For welding with four methods: MIG/MAG AUTO, MIG/MAG, LIFT-TIG and MMA.

The FAN STOP system turns off the fan - so the welding machine is silent when it is on and fully functional, saves energy and attracts less dust. The fan switches on automatically when welding starts.

A SPOOL GUN holder (with integrated wire feeder) can be connected, which improves the transfer of material to the joint.

The device adjusts the welding current after the thickness of the material has been selected using the LIFT-TIG method. In the MMA method, after setting the material thickness, parameters and electrode diameter are proposed.

Handy selectors and a transparent panel make it easier to quickly start up the welding machine, even when wearing welding gloves.

2T welding. To start the arc, press and hold the torch button to weld, releasing the button will turn off the welding arc.

4T welding. The arc triggers a continuous arc by pressing and releasing the welding torch button. The arc is turned off by pressing and releasing the button again.

SPOT functions - designed for spot welding. The machine has a preset warm-up time and the user just sets the welding current. This function is mostly used in car repair shops

S_2T / S_4T functions - combines two welding techniques. Spot welding, where shielding gas is removed both before and after the welding process. In addition, 2T and 4T functions are used together in the S_2T/S_4 method so that welding starts and ends correctly.

Built with efficient IGBT components.

Functions of the welding machine

MIG/MAG AUTO welding

Automatic setting of the welding machine: after selecting the material, thickness and diameter of the wire, the machine sets itself to the optimal parameters. The welding current and other settings can be fine-tuned manually.

PULSE welding improves the transfer of filler material to the welding pool, which improves the quality and strength of the joint.

Optional 2T/4T for making longer welds more comfortably.

Selection of welding material (carbon steel, stainless steel, Al-Si - soft aluminum, Al-Mg - hard aluminum, Cu-Si - solder).

MIG/MAG welding

PULSE welding, which improves the transfer of the filler material to the weld pool, which improves the quality and strength of the weld.

2T/4T selection, for making longer welds more comfortably.

The SPOT welding function and support for S_2T and S_4T welding, i.e. shielding gas flows before and after the welding process, which rises from a lower current to the basic current and finally decreases again to the crater suppression setting.

Selection of welding materials (carbon steel, stainless steel, Al-Si - soft aluminum, Al-Mg - hard aluminum, Cu-Si - solder).

Selection of the thickness of the welding material.

Determination of wire diameter. Al-Si and Al-Mg (range 1.0-1.2), other materials (0.8-1.2).

Wire feed speed setting [m/min].

Welding current voltage setting [V].

Inductance adjustment ± [%].

Pulse frequency setting in pulse mode [Hz].

Pulse cycle adjustment [%].

MIG/MAG DUAL PULSE hot sauce

Peak feed rate [m/min].

Basic yarn feed speed [m/min].

Adjustable double pulse frequency [Hz].

Adjustable double pulse power [%].

MMA welding

Hot Start - enhances the start of welding by temporarily increasing the welding current at the beginning.

Arc Force - adjusts the length of the welding arc, reduces or increases the depth of fusion and reduces spatter.

VRD - extinguishes the arc when the electrode separates from the material for a safer welding environment.

Anti Stick - easier to remove electrodes when sticking.

LIFT-TIG hits out

Adjustable welding current [A], when the welding machine is set, it will indicate the thickness of the plate.

The LIFT-TIG function is equipped with a SOFT START module so that there is no risk of damaging the stick when starting the welding process.

Press and hold the "Return" button to restore factory settings.

Technical information

POWER SOURCE PARAMETERS

Power supply: 230 V

Frequency: 50/60 Hz

No-load voltage: 68 V

TECHNICAL PARAMETERS

MIG welding current: 40-200 A

MIG welding voltage: 16-24 V

Efficiency (at 40°C):

60% / 200 A / 24 V

100%/ 155 A/21.8 V

TIG welding current: 10-200 A

TIG welding voltage: 10.4-18 V

TIG efficiency (at 40 °C):

60%/200A/18V

100%/155A/16.2V

Stick welding current: 30-200 A

Stick welding voltage: 21.2-28 V

MMA efficiency (at 40 °C):

60 %/200A/28V

100%/155A/26.2V

Input device: 4 R

Thread spool diameters: D200

Maximum reel size: 5 kg

Diameter of the wire used in the welding machine: 0.8/1.0/1.2 [mm].

PHYSICAL DATA

Length x width x height: 48 × 21 × 38 [cm].

Weight: welding machine [net] 14.8 [kg], in box [gross] 21 [kg]

4-roll wire feeder for smooth wire transfer: yes

PULSSI and DUAL PULSE for better quality welding: yes

FAN STOP - turning off the fan when not in use: yes

Quick-connect gas hose (TYPE 21) connection: yes

SPOOL GUN external thread feeder connection: yes

VRD voltage reduction and safety improvement: yes

Arc Force welding arc length adjustment: yes

Hot Start fast arc ignition: yes

Anti Stick prevents electrodes from sticking: yes

Memory channels: 18

SKANDI KRAFT iTECH MIG 220 4R welding machine with integrated 3 m 3x2.5 [mm2] power cord

MIG torch KD24 type MB24 4 meters with Teflon graphite insert

Blue extra steel insert 4 meters for KD24 torch, for welding with wire diameter 0.6 -1.0 [mm]

All-copper electrode holder 3 meters, cross-section 25 [mm2]

Wire rolls: for steel 2x 0.8-1.0 V, for aluminum 2x 1.0-1.2 U.

Wire feed rollers size 22/10/30 [mm].

Gas cylinder mounting parts: 2 x gas regulator mounting clamps, 2 m gas hose, spanner, Allen key

Virtasuutin KD24, MB24 poltimelle (1x 0,8; 1x1,0; 1x1,0 ALU; 1x1,2 ALU)

User manual.

SKANDI KRAFT iTECH MIG 220 4R

Sale price€1.829,00 EUR

Regular price (/)